The end of last year in Salt Lake City in the United States saw an introduction of a truck prototype, Nikola One, with an electric drivetrain of four electric motors with a 750 kW capacity and 2700 Nm torque. Its total range is estimated to be nearly 2000 km. That is possible thanks to a hybrid system of Li-ion batteries with a 320 kWh capacity and fuel cells. Depending on the results of a pending prototype test, the engineers may decide to switch to a less powerful, and subsequently lighter, battery pack which will, irrespective of their decision, ensure a range between 160 and 320 km without an extra charge. The difference between the 2000 km mentioned above and this estimate will be taken care of by the fuel cells, deriving hydrogen from the vehicle's tank.

ELECTRICITY FROM FUEL CELLS AND THE GRID

Nikola One will also qualify as a plug-in hybrid that will enable battery charging from the network, during stopovers. An external plug will provide power to all devices in the sleeper berth of the trucks designed for long-haul transport. Because of different regulations in terms of vehicle length, such American trucks (unlike European ones) come with a much more spacious sleeper, and often are more ravenous consumers of electric power. At the introduction of the prototype, that took about four years to develop, the founder of Nikola Motors Company, Trevor Milton, announced additional improvements and alterations for the production version of this electric freight truck, which is estimated to reach the first buyers in 2020. The key construction elements will remain intact.

TECHNOLOGICAL AND SERVICE ORIGINALITY

Nikola One is a technological phenomenon, not only because of the electric propulsion and combined provisions of battery-derived electricity and fuel cells, but also because of numerous design and content idiosyncrasies. Among the most conspicuous is the cabin, designed to provide better aerodynamic properties.

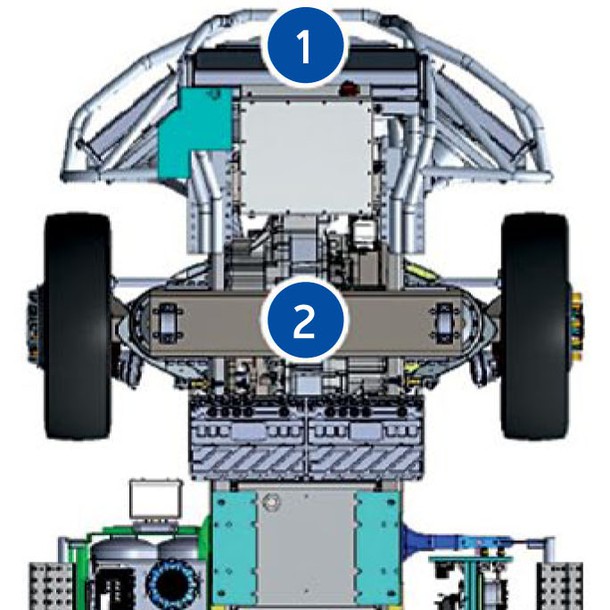

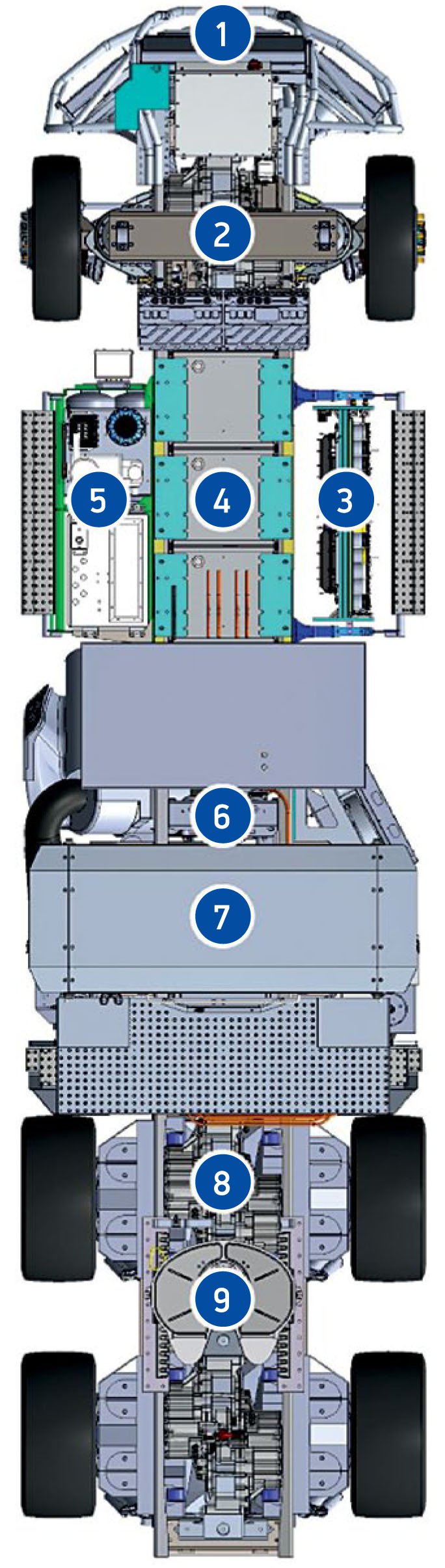

1 – an assembly of radiators and motor cooling units, fuel cells, transmissions, batteries and a cabin 2 – an assembly of the front two electric motors and transmissions 3 – power-electronics in control of fuel cell operation and battery charging 4 – battery storage system of 32,000 individual Li-ion cells with total capacity of 320 kWh 5 – chiller providing cold fluid to cool the batteries and air tanks for backup disc brakes 6 – fuel cells with 300 kW output 7 – hydrogen tanks 8 – load-bearing housing with suspension for a reardrive electric motor and gearboxes 9 – aluminum coupling for connecting a semi-trailer

Conceptually closer to aircraft cabins, this design is believed to provide easier and safer entrance, unhindered by the seat—the driver can actually walk into the cabin before taking the seat. Unlike the prototype, which is equipped with only one door, the production truck will have two doors, one on each side of the cabin. The driver will be able to access the cabin without a key, thanks to the biometric sensors with the ability to recognize the driver and adjust the workings of the truck based on his or her personal settings. Because there's no conventional engine in the nose of the truck, the wheels of which are powered directly by four separate electric torque vectoring motors, weight distribution is more even and safer to operate. Among the traits special to

Nikola One, the NMC Group highlights a fully-digital instrument panel for vehicle control, open to software updates and new functions. The user interface will generate information about the route and rest stops ahead, while also enabling communication with service stations, and scheduling a servicing appointment. Remotely monitored by the servicing team, the truck will be more likely to avert severe mechanical difficulties with adequate and timely servicing at hand. The future network of hydrogen filling stations will ease the process of payment by having the stations recognize the vehicle, to take care of formalities, including state-imposed taxes on hydrogen that will initially be free of charge for Nikola One buyers.

NEW HYDROGEN NETWORK

Nikola Motors Company geared up for the electric trucks to gain a foothold in the North American market with a lot of forethought, as well as by forming partnerships in the world of transport. Potential buyers understandably seem to lack interest in new alternative propulsion technologies, especially considering how time-consuming it is to build a hydrogen infrastructure. As a result, NMC introduced Nikola One along with a construction plan for 364 hydrogen filling stations, with the objective to sustain hydrogen-powered vehicles across the entire United States. Although such a network is estimated to take ten years to finish, the very first stations will be ready as early as in 2019. Each of them will be equipped with 5 to 10 hydrogen-filling spaces, which will provide 1.6 million kilometers' worth of hydrogen to Nikola One truck drivers at no extra fee, along with electricity demands, during a stopover. Empty hydrogen tanks should take from 5 to 10 minutes to fill. Hydrogen that will be generated independently via electrolysis and with the help of solar energy will be offered to other users against a fee. Construction of one hydrogen filling station is allegedly valued at 1 to 3 million USD, but given the expected increase in demand for fuel-cell vehicles (assuming hydrogen infrastructure is well underway), pushing forward with revolutionary changes in transport will make for a good investment.

OVER 8000 PRE-ORDERS

Nikola Motors Company attests to having received over 8000 orders for their serial vehicles, even if they're scheduled to go into production in a few years' time. In the meantime, the prototype will have to be submitted to numerous tests, in order to be certified for public use. Initially, the trucks will be manufactured in Utah, at a rate of approximately 5000 units per year, while their maintenance and repair will be passed to a well-established fleet maintenance company, Ryder, which prides itself on having maintenance shops throughout the United States. Nikola One trucks will be offered largely on lease for a seven-year period, under a warranty and monthly payment of 5000 USD. The trucks will be available for purchase, but the prices for production units are not yet known. But with many unknowns yet to be resolved, the course of events may stray from the optimistic plans that were revealed at the Nikola One prototype presentation.