For a while now, we've all been reading and discussing the astonishing things we can achieve with the modern 3D printing technologies. This is it, 3D printing! ... But, as it often happens due to rapid development in technology and science, 3D printing is almost what you might call 'yesterday's news'. Indeed, science has gone another step further, introducing another dimension to the printing technology, the 4th D that is time.

The new microscale printing process was developed under the leadership of Jennifer Lewis, a materials scientist at Harvard, joined by a team of scientists at the Wyss Institute for Biologically Inspired Engineering at Harvard University and the Harvard John A. Paulson School of Engineering and Applied Sciences (SEAS).

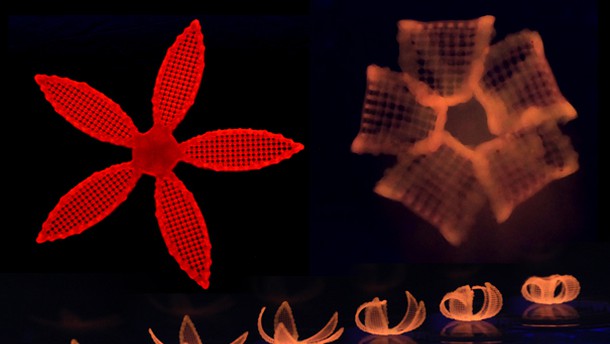

Scientists revealed 4D-printed hydrogel composite structures that transform when immersed in water, mimicing natural processes of plants, which are known to change shape over time in response to environmental stimuli such as humidity or temperature.

Structures were printed using a hydrogel composite ink containing aligned cellulose fibrils, which enable anisotropic swelling. According to press release, by aligning cellulose fibrils during printing, the hydrogel composite ink is programmed with precise, localized anisotropic swelling and stiffness, patterned by a proprietary mathematical model to produce prescribed transformable shapes.

This new method shows great potential for 4D printing technology, as it could be implemented to produce smart textiles, soft electronics, biomedical devices, and play an integral role in tissue engineering.

"What's remarkable about this 4D printing advance made by Jennifer and her team is that it enables the design of almost any arbitrary, transformable shape from a wide range of available materials with different properties and potential applications, truly establishing a new platform for printing self-assembling, dynamic microscale structures that could be applied to a broad range of industrial and medical applications," said Wyss Institute Director Donald Ingber, the Judah Folkman Professor of Vascular Biology at Harvard Medical School and the vascular biology program at Boston Children's Hospital and professor of bioengineering at SEAS.

Watch the captivating video below.